I-QDF-400 WP Isistimu Yokukhiqiza Eqhubekayo Ye-Jet Mill Ngo-400kg

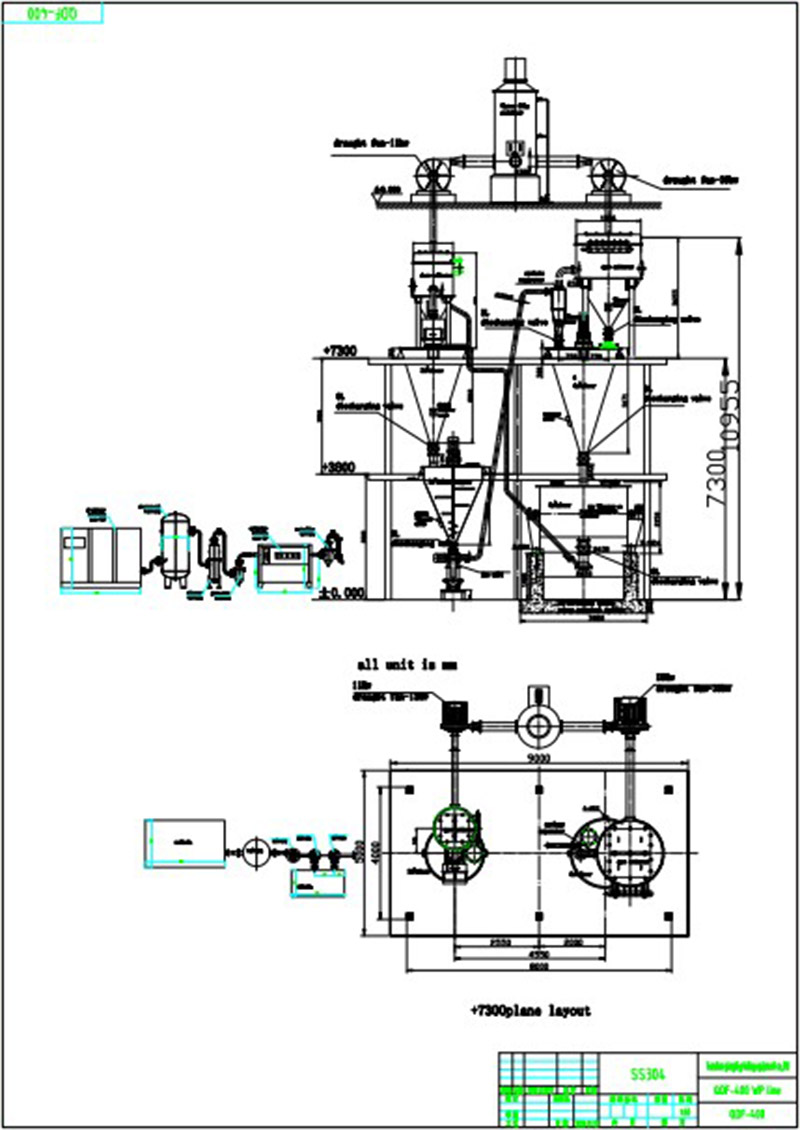

Ulayini we-WP odume kakhulu ePakistan-QDF-400 uhlelo lokukhiqiza oluqhubekayo njengoba ngezansi komdwebo we-Flow nesithombe

Okokuqala,Isiphakeli se-Raw material esivela kusiphakeli --ukudluliswa kwempahla kuya kumamitha amathathu okuqala3i-mixer ye-premixing, kanye nomqoqi wothuli uzoqoqa uthuli ngesikhathi sokuphakela, bese kuba ngu-3m3isitolo se-hopper esixubile, bese ungena ku-jet Mill ukuze ugaywe, usayizi wezinhlayiyana ophumayo ungashintshwa ngokulungisa isivinini esijikelezayo esihlukile sesondo le-classifier,. Ngemva kokugaya, izinto zizodlulela esivunguvungwini ngokusebenzisa amandla amaphakathi efeni elisalungiswa kanye nomqoqi wothuli phezulu kwe-4m yokuqala.3mixer, bese udlulisela ku-4m yesibili3ingxube yeribhoni evundlile ukuze ixutshwe ngaphambi kwephakheji noma idluliselwe ohlelweni lwe-WDG.

1.Inqubo yokugaya isebenzisa isimiso sokusebenza se-fluidized-bed jet jet ngekhono eliphezulu, futhi ukusabalalisa usayizi wezinhlayiyana kufana.

I-2.Inqubo yokondla ihambisana nokuthuthwa komoya kwe-minus, i-exhauster yengezwa ukuvimbela ukuphuma kothuli.

3.Kokubili inqubo yokuqala neyokugcina yokuhlanganisa kusetshenziswa izixube zezikulufu eziphindwe kabili noma i-blender yeribhoni evundlile evundlile eqinisekisa ukuthi ukuxuba kwanele futhi kuyalingana.

I-4.I-outlet yomkhiqizo ingaxhuma ngokuqondile emshinini wokupakisha ngokuzenzakalela.

5.Lonke uhlelo lulawulwa ngesilawuli esikude se-PLC. Ukusebenza okulula nokugcinwa, ukusebenza kwemishini okuzenzakalelayo.

6.Ukusetshenziswa kwamandla okuphansi: kungonga u-30%~40% wamandla uma kuqhathaniswa namanye ama-pulverizer womoya womoya.

7. Kusebenza ekugxotsheni izinto ezisezingeni eliphezulu zokuhlanganisa okunzima kokuchotshozwa kanye nezinto ezibonakalayo.

Isistimu yomthombo womoya- i-compressor yomoya, isikhiphi sikawoyela, ithangi lokugcina umoya, isomisi esiqandisa umoya, isihlungi esinembile.

WorkingPrinciple

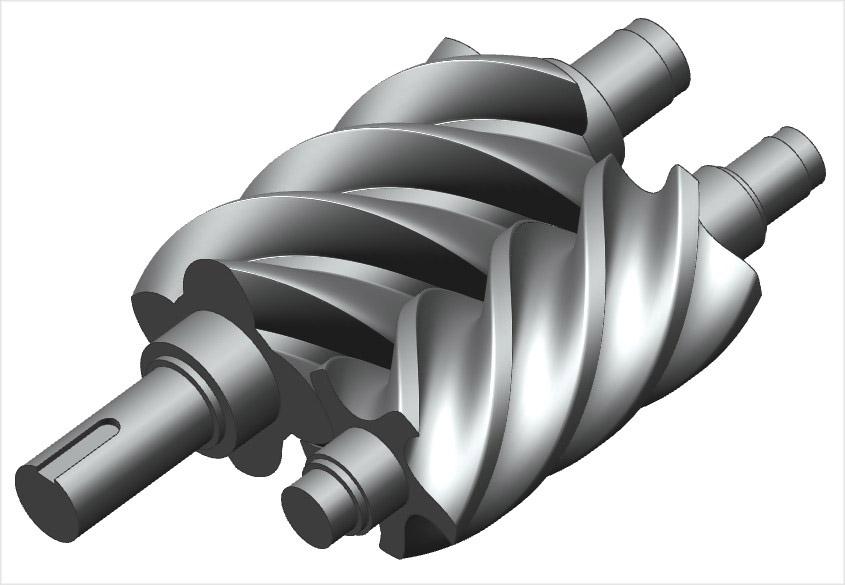

I-Compressor isetshenziselwa ukucindezela umoya, isiteji esisodwa, ejovwe uwoyela futhi ishayelwa yinjini, okuhlanganisa indawo yomoya, injini, isihlukanisi sikawoyela/igesi, isipholile sikawoyela, isipholile somoya, isiphephetha-moya (sohlobo olupholile kuphela), isicupho somswakama, iKhabhinethi yokulawula ugesi, ipayipi legesi, ipayipi likawoyela kanye nepayipi lamanzi (ohlotsheni olupholiswe amanzi kuphela), uhlelo lokubhanqa ngaphakathi kukhona i-rogator system. I-rotor yesilisa inamazinyo ama-4, i-rotor yesifazane inamazinyo ayi-6. I-rotor yesifazane ilandelwa i-rotor yesilisa ngesivinini esikhulu. Ngokugudluzwa kwamazinyo ngaphansi kwama-rotor angu-2, umoya ophuma kusihlungi se-inlet namafutha agcotshiwe asuka ku-casing acindezelwa kancane kancane ngomfutho ophezulu. Uma ukususwa kwamazinyo kuqonde ngqo endaweni yokuphuma, ingxube yomoya/uwoyela ocindezelwe igeleza isuka endaweni yokuphuma, bese igelezela kusihlukanisi sikawoyela/igesi ukuhlukanisa uwoyela nomoya. Okulandelayo, ukugeleza komoya ngevalvu yokucindezela okuncane, indawo epholile komoya kanye nesicupho somswakama, ekugcineni uye epayipini lokulethwa komoya. Uwoyela ohlukanisiwe wehlela ezansi kwesihlukanisi, bese ugelezela endaweni epholile kawoyela, isihlungi sikawoyela futhi ekugcineni uye ekugcineni ukuze usetshenziswe kabusha ngenxa yokucindezela okuhlukile.

Isimiso Sokusebenza

Umoya oshisayo noswakeme futhi obandayo wokufaka izishintshisi zokushisa ezipholile kuqala (i-evaporator ephuma emoyeni obandayo ocindezelwe ukuya ekushintshisaneni kokushisa) ukuze kwehliswe umthwalo ku-evaporator, kuyilapho kushisisa umoya ocindezelwe okhishwe emakhazeni, kude nokugcwala. Khona-ke ingena evaporator yabuye yapholiswa kuya ku-12 ℃ ngezansi, ukungena kabusha isihlukanisi kuyoba kwemvula inqubo yokupholisa amanzi ziye zahlukaniswa, entabeni sub-Shui idivayisi ukukhishwa. Kuphuma emoyeni obandayo owomile ekushiseni okukhishwa isishintshi sokushisa sangaphambi kokupholisa.

Isimiso Sokusebenza

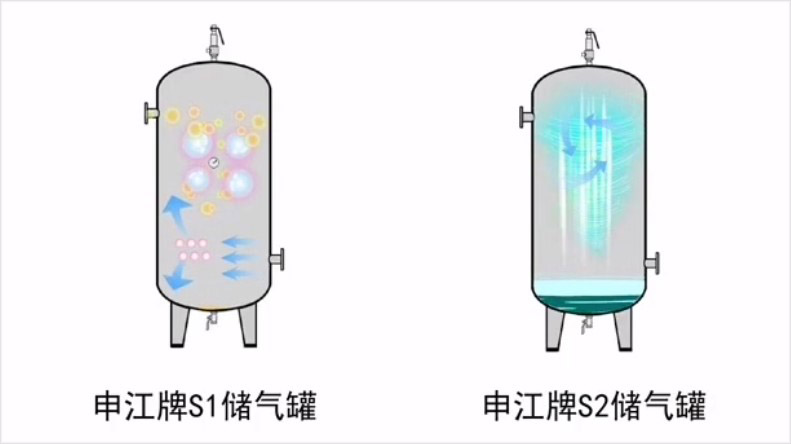

ithangi lokugcina umoya (umkhumbi wokucindezela), owaziwa nangokuthi ithangi lokugcina umoya elicindezelwe, umkhumbi wokucindezela osetshenziselwa ngokukhethekile ukugcina umoya ocindezelweyo. Isetshenziselwa kakhulu ukugcina isivimbeli segesi, futhi idlala indima yokusimamisa ingcindezi yesistimu, ukuze kugwenywe ukulayishwa njalo nokuthulula i-compressor yomoya futhi ikhiphe amanzi amaningi awuketshezi.Ithangi lokugcina igesi ngokuvamile lakhiwa umzimba we-cylinder, ikhanda, i-flange, imibhobho, izakhi zokuvala nezisekelo nezinye izingxenye kanye nezingxenye. izinqubo.

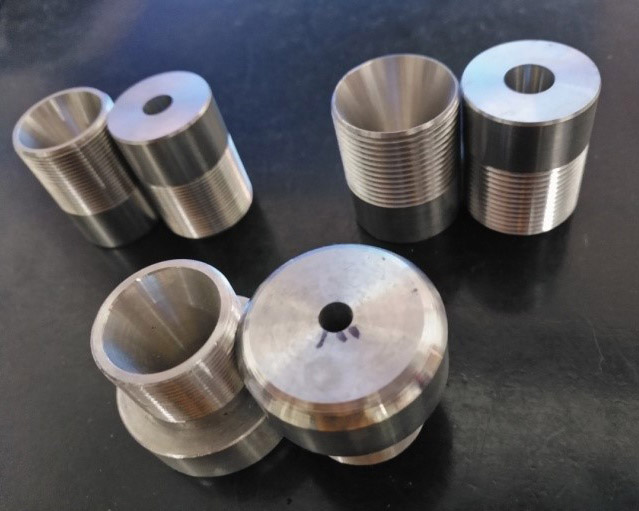

Umkhiqizo uyi-pulverizer yombhede ewuketshezi enomoya wokuminyanisa njengendlela yokuchoboza. Umzimba wokugaya uhlukaniswe izigaba ezi-3, okungukuthi indawo yokuchoboza, indawo yokudlulisela kanye nendawo yokugreda. Indawo Yokugreda ihlinzekwa ngesondo lokugreda, futhi isivinini singalungiswa yisiguquli. Igumbi lokuchoboza lakhiwe ngombhobho ochotshozayo, i-feeder, njll. I-disc yokuhambisa umoya eyindandatho ngaphandle kwebhokisi elichotshozwayo lixhunywe nombhobho ochotshozayo.

Isigayo seJet- Ngaphansi kwesenzo samandla aphakathi nendawo wesondo lokuhlukanisa kanye namandla amaphakathi efeni elisalungiswa,izinto ezisetshenziswayo ziba umbhede owuketshezi ngaphakathi kwe-jet mill.ngalokho kuthola impushana ehlukile .

Isistimu yokulawula ye-PLC- Uhlelo lwamukela isilawuli sesikrini sokuthinta esihlakaniphile, ukusebenza okulula nokulawula okunembile. Lolu hlelo lusebenzisa imodi yokulawula isikrini sokuthinta esithuthukisiwe se-PLC +, isikrini sokuthinta siyindawo yokusebenza yalesi simiso, ngakho-ke, kubaluleke kakhulu.ukubamba ngokunembile zonke izici zokhiye esikrinini esithintwayo ukuze uqinisekise ukusebenza kahle kwalolu hlelo.

Umphakeli ophezulu-Ixhumeke ngendlela eguquguqukayo kusiqoqi sothuli ukugwema ukuvuza uthuli, olutholakalayo ukuze luphakelwe ngokuqhubekayo.

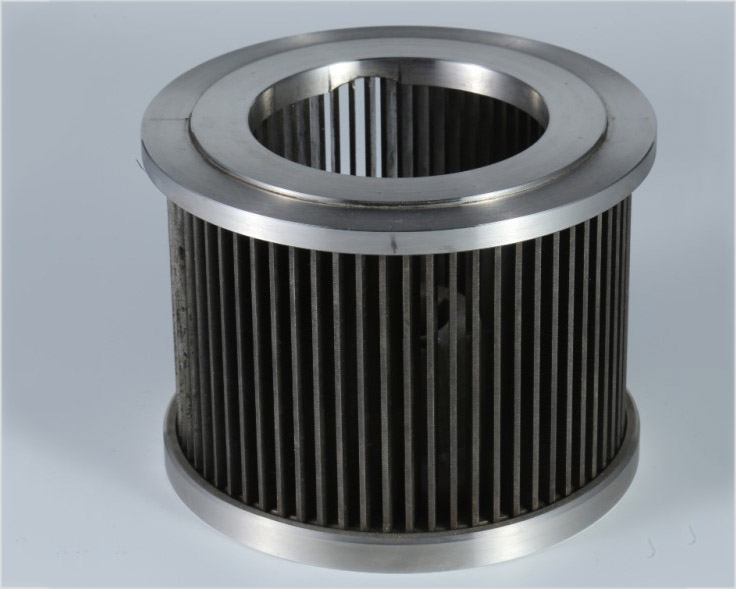

Isihlukanisi sesishingishane nesiqoqi uthuli-Imikhiqizo eqoqwayo kanye nokuqoqwa kothuli ihlakaza indlela yokuhamba kwezinto ezingavuthiwe futhi igweme ukunqwabelana kwezinto. Ukuqinisekisa ukugaywa kabusha kothuli ohlelweni lokukhiqiza ukuze kuhlangatshezwane nemfuneko yokuvikelwa kwemvelo yokukhiqiza okuhlanzekile kanye nokukhipha umoya.

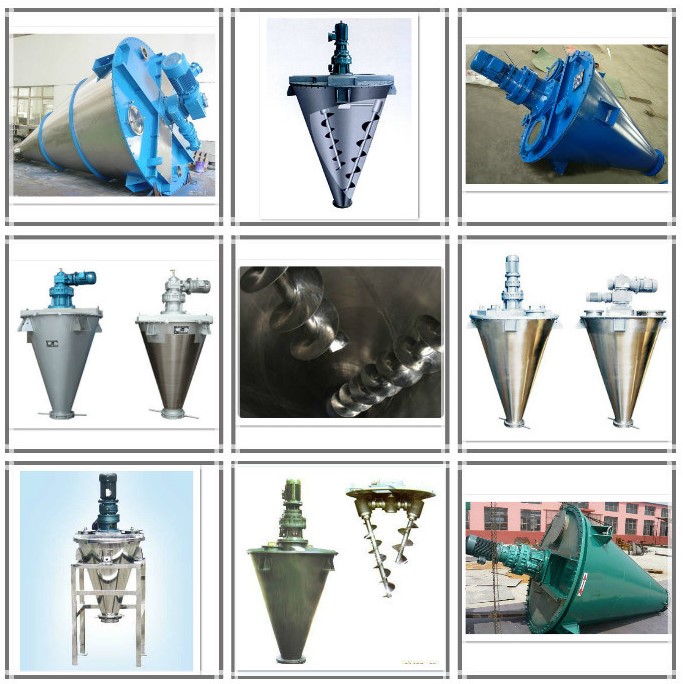

I-Twin screw mixer-ine-stirrer ende kanye ne-screw design, egcina ukuxuba ngokuphelele okubalulekile ekuzinzeni ngaphansi kwesenzo soguquko nokuzungezisa.

Isimiso sokusebenza

I-twin screw mixer ihlanganisa impushana, i-granule nokuxuba uketshezi. Ukuzungezisa kwe-twin screw mixer kuqedwa isethi yezinjini nezinciphisi ze-cycloid. Ngokuxutshwa kwe-asymmetric ngezikulufu ezimbili, ububanzi obushukumisayo buzonwetshwa futhi isivinini esishukumisayo sizosheshisa. Umshini wokuhlanganisa ukhuthazwa ama-spiral amabili a-asymmetric wokuzungezisa okusheshayo, okwenza amakholomu amabili asontekile angalingani agelezela phezulu esuka odongeni lwesilinda. Ingalo ephendukayo eqhutshwa i-spiral orbit, yenza i-spiral material yezinga elihlukile ibe yi-stud emvilophini, i-slocation ingxenye yento ethuthukiswayo, enye ingxenye yento ephonswa isikulufu, ukuze kuzuzwe izinto ezithwala umbuthano ogcwele zibuyekezwa njalo.

Isihlanganisi seribhoni esivundlile esivundlile-Kulula kakhulu ukwenza imikhiqizo ethile edinga ukwengeza i-adjuvant noma amanye amakhemikhali emkhiqizweni osuphelile. Futhi ukuxuba kungcono kakhulu futhi kunembe kakhulu kune-twin screw mixer. ubude bomzimba obuphansi kune-Twin screw mixer, kulula ukuyifaka.

Umgomo wokusebenza:

Isihlanganisi seribhoni esivundlile esiphindwe kabili sinethangi elivundlile elimise okwe-U, ikhava ephezulu enezimbobo (noma ezingenakho), i-shaft eyodwa efakwe i-agitator yokuxuba iribhoni enezingqimba ezimbili, iyunithi yokudlulisela, ifreyimu yokusekela, isici sokuvala, isakhiwo sokukhipha nokunye. Ama-Ribbon blades ahlala ayizingqimba ezimbili. Iribhoni yoqweqwe lwangaphandle yenza izinto ezisetshenziswayo zihlangane kusukela emaphethelweni amabili kuya enkabeni futhi iribhoni yoqweqwe lwangaphakathi yenza izinto ezisetshenziswayo zisabalale ukusuka enkabeni kuye emaphethelweni amabili. Izinto zokwakha zakha i-vortex ngesikhathi sokunyakaza okuphindaphindiwe futhi ukuxuba okulinganayo kufinyelelwa.

Ifeni esalungiswa- Yenza lonke uhlelo lwe-WP ngaphansi kwengcindezi engemihle ngamandla e-centrifugal we-draft fan, ngaleyo ndlela uqhube izinto ezibonakalayo ukuze uchoboze futhi ukhulule i-exhaust gas ohlelweni lokugaya.

I-scrubber yamanzi- Impushana engaphansi kuka-0.5um ingena ku-scrubber samanzi futhi imuncwe ungqimba lwefilimu yamanzi, ilahlwe kanye nekhoni engezansi yokugeleza kwamanzi.ukugwema indawo engcolisa uthuli.

Igesi equkethe uthuli yethulwa ngokuhambisana ne-tangential isuka engxenyeni engezansi yesilinda futhi izungeza phezulu. Izinhlayiya zothuli zihlukaniswa ngamandla e-centrifugal futhi ziphonswe odongeni lwangaphakathi lwesilinda. Akhangiswa ungqimba lwefilimu lwamanzi olugeleza odongeni lwangaphakathi lwesilinda futhi akhishwe endaweni yokuphuma uthuli kanye nekhoni engezansi yokugeleza kwamanzi.Ifilimu yamanzi yakhiwa imibhobho eminingana ehlelwe engxenyeni engenhla yesilinda ukuze ifafaze amanzi nge-tangentially odongeni lwesilinda. umphumela wokukhipha uthuli.