Imboni Yebhethri Kanye Nenye I-Chemical Material Sebenzisa I-Fluidized-bed Jet Mill

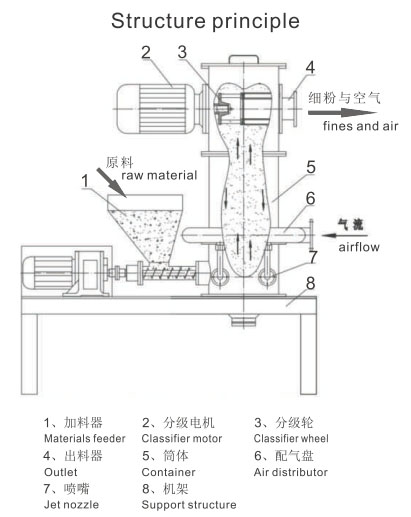

I-fluidized bed pneumatic mill iyisisetshenziswa esisetshenziswa ukuchoboza izinto ezomile zibe yimpushana, ngesakhiwo esiyisisekelo kanje:

Umkhiqizo uyi-pulverizer yombhede ewuketshezi enomoya wokuminyanisa njengendlela yokuchoboza. Umzimba wokugaya uhlukaniswe izigaba ezi-3, okungukuthi indawo yokuchoboza, indawo yokudlulisela kanye nendawo yokugreda. Indawo Yokugreda ihlinzekwa ngesondo lokugreda, futhi isivinini singalungiswa yisiguquli. Igumbi lokuchoboza lakhiwe ngombhobho ochotshozayo, i-feeder, njll. I-ring sir supply disc ngaphandle kwe-canister echotshozwayo ixhunywe nombhobho ochotshozayo.

Impahla ingena egumbini lokuchoboza ngesiphakeli sezinto ezibonakalayo. Imibhobho yomoya yokucindezelwa ingena egumbini lokuchoboza ngesivinini esikhulu ngokusebenzisa imibhobho echotshozwayo efakwe ngokukhethekile. Izinto zithola ukusheshisa ekugelezeni kwejethi ye-ultrasonic futhi zibe nomthelela ngokuphindaphindiwe futhi zishayisane endaweni ephakathi yokuhlangana yegumbi elichotshozwayo kuze kube yilapho ichotshozwa. Impahla echotshoziwe ingena egunjini lokugreda nokukhuphukayo. Ngenxa yokuthi amasondo okugreda ajikeleza ngesivinini esikhulu, lapho impahla ikhuphuka, izinhlayiya zingaphansi kwamandla aphakathi nendawo adalwe kusuka kumarotha okugreda kanye namandla amaphakathi adalwe kusuka ku-viscosity yokugeleza komoya. Uma izinhlayiya zingaphansi kwamandla aphakathi nendawo amakhulu kunamandla amaphakathi, izinhlayiya ezimahhadla ezinobukhulu obukhulu kunezinhlayiya zokugreda ezidingekayo ngeke zingene ekamelweni elingaphakathi lesondo lokugreda futhi zizobuyela ekamelweni lokuchotshozwa. Izinhlayiya ezinhle ezihambisana nobubanzi bezinhlayiya zokugreda ezidingekayo zizongena esondo lokugreda futhi zigelezele kusihlukanisi sesishingishane segumbi elingaphakathi lesondo lokugreda nokugeleza komoya futhi ziqoqwe ngumqoqi. Umoya ohlungiwe ukhishwa kumshini wokungenisa umoya ngemva kokwelashwa kwesikhwama sokuhlunga.

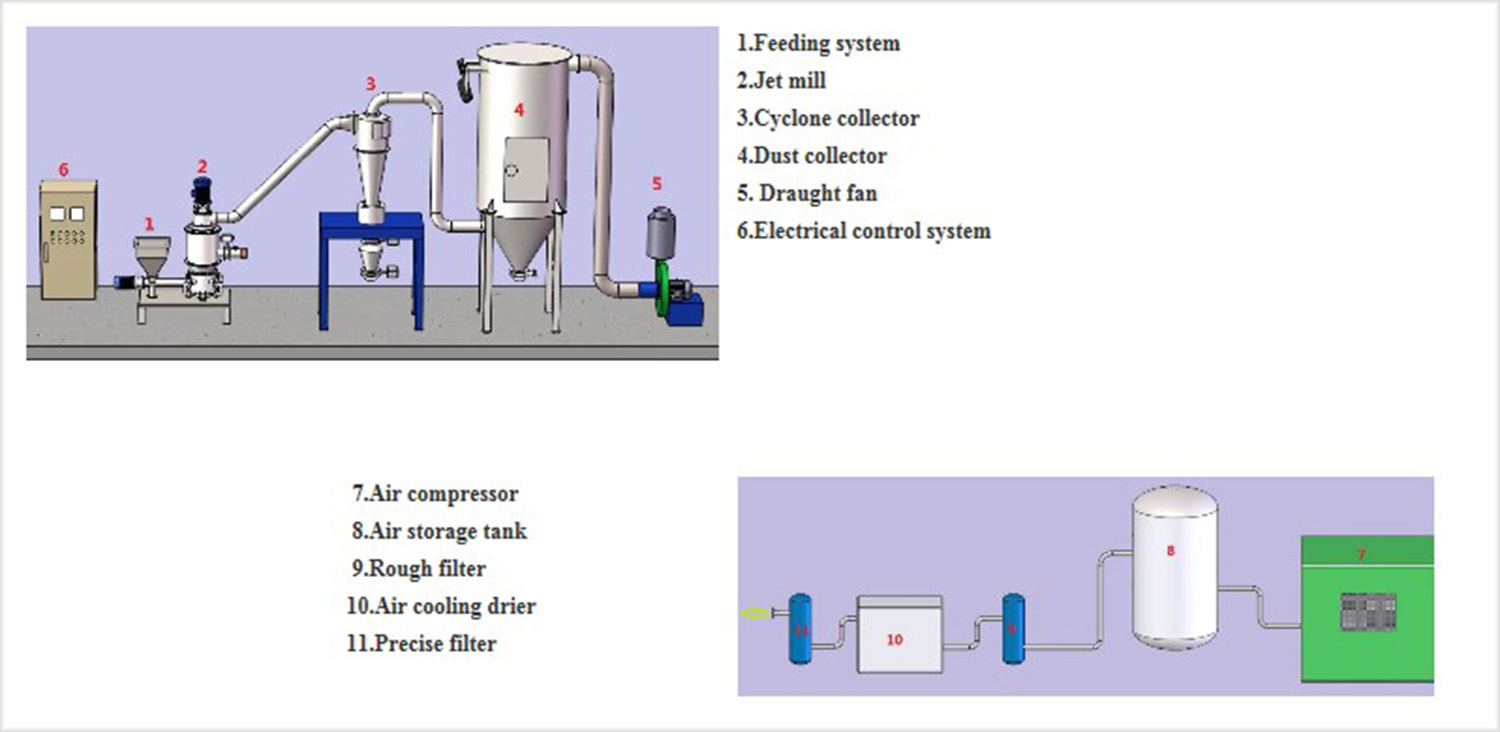

I-pulverizer ye-pneumatic yakhiwa i-compressor yomoya, i-remorer kawoyela, ithangi legesi, okomisa iqhwa, isihlungi somoya, i-fluidized bed pneumatic pulverizer, isihlukanisi sesivunguvungu, umqoqi, i-air intaker nokunye.

Bonisa imininingwane

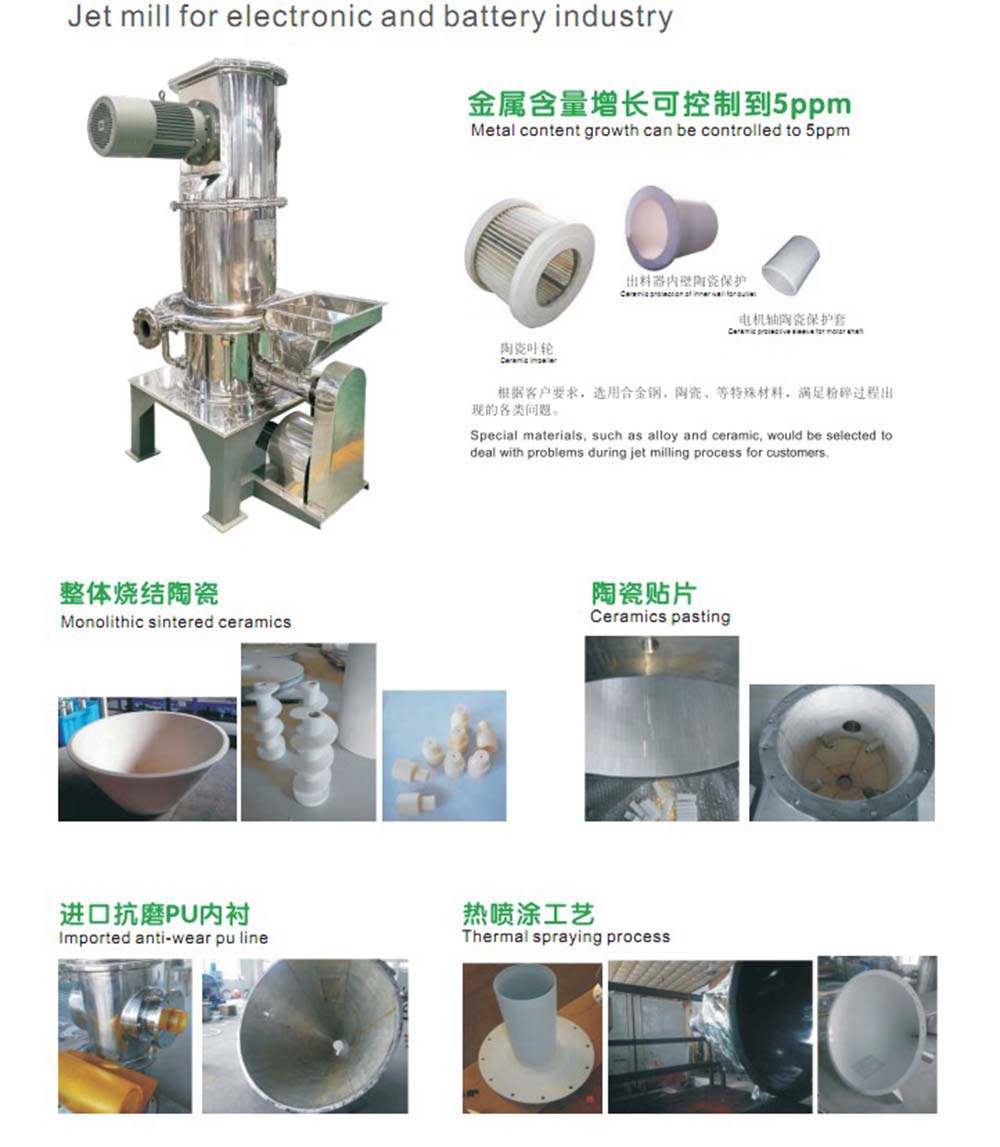

Ukunamathisela ama-Ceramics kanye ne-PU lining ezingxenyeni eziphelele zokugaya ezithintana nemikhiqizo ukuze kugwenywe insimbi engalahliwe eholela emphumeleni ongavumelekile wemikhiqizo ebulalayo.

I-1.Izimbozo ze-ceramic eziqondile, i-100% iqeda ukungcoliswa kwensimbi kusukela kunqubo yokuhlukanisa izinto ezibonakalayo ukuze kuqinisekiswe ukuhlanzeka kwemikhiqizo. Ikakhulukazi ezifanele izidingo zokuqukethwe kwensimbi yezinto zikagesi, njenge-cobalt high acid, i-lithium manganese acid, i-lithium iron phosphate, i-Ternary Material, i-lithium carbonate ne-Acid lithium nickel kanye ne-cobalt njll yebhethri impahla ye-cathode.

2. Akukho ukwenyuka kwezinga lokushisa: Izinga lokushisa ngeke likhuphuke njengoba izinto zilungiswa ngaphansi kwezimo zokusebenza zokunwetshwa kwe-pneumatic futhi izinga lokushisa endaweni yokugaya ligcinwa lijwayelekile.

3.Ukubekezela: Kusetshenziswa ezintweni ezinobulukhuni be-Mohs ngaphansi kweBanga lesi-9. njengoba umphumela wokugaya uhilela kuphela umthelela nokushayisana kwezinhlamvu kunokungqubuzana nodonga.

4.Amandla asebenzayo: Yonga u-30% -40% uma kuqhathaniswa namanye ama-pulverizer womoya womoya.

I-5.I-inert gas ingasetshenziswa njengemidiya yokugaya izinto ezivuthayo neziqhumayo.

6. Lonke uhlelo luchotshoziwe, uthuli luphansi, umsindo uphansi, inqubo yokukhiqiza ihlanzekile nokuvikelwa kwemvelo.

7. Uhlelo lwamukela isilawuli sesikrini sokuthinta esihlakaniphile, ukusebenza okulula nokulawula okunembile.

8.Isakhiwo esihlangene: Igumbi lomshini omkhulu lihlanganisa isifunda sokuvala ukuchotshozwa.

Ishadi eligelezayo liwukucubungula okujwayelekile kokugaya, futhi lingalungiselelwa amakhasimende.

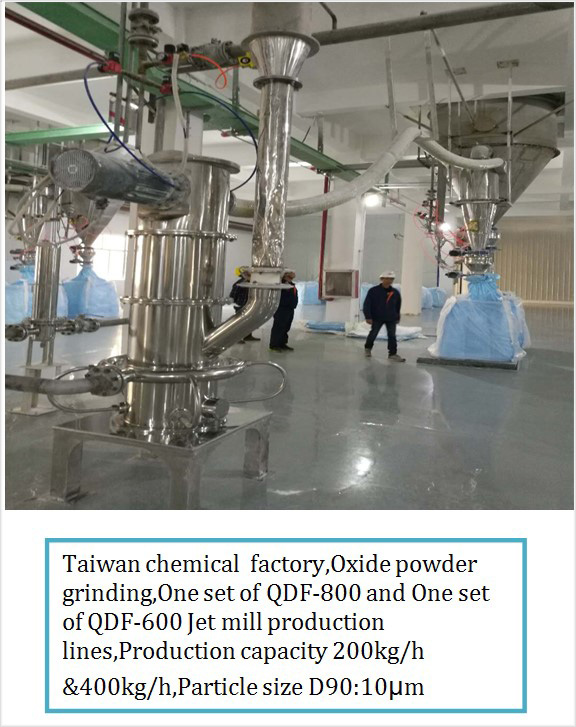

| imodeli | QDF-120 | QDF-200 | QDF-300 | QDF-400 | QDF-600 | QDF-800 |

| Ingcindezi yokusebenza (Mpa) | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 | 0.75~0,85 |

| Ukusetshenziswa komoya (m3/min) | 2 | 3 | 6 | 10 | 20 | 40 |

| Ububanzi bento ephakelwayo (i-mesh) | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 | 100~325 |

| Ubuhle bokuchoboza (d97μm) | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 | 0.5~80 |

| Amandla (kg/h) | 0.5~15 | 10-120 | 50~260 | 80-450 | 200 ~ 600 | 400 ~ 1500 |

| Amandla afakiwe (kw) | 20 | 40 | 57 | 88 | 176 | 349 |

| Okubalulekile | Uhlobo | Ububanzi bezinhlayiya eziphakelwe | Ububanzi bezinhlayiya ezikhishiwe | Okukhiphayo(kg/h) | Ukusetshenziswa komoya (m3/min) |

| I-Cerium oxide | QDF300 | 400(Mesh) | d97, 4.69μm | 30 | 6 |

| I-flame retardant | QDF300 | 400(Mesh) | d97,8.04μm | 10 | 6 |

| I-Chromium | QDF300 | 150(Mesh) | d97, 4.50μm | 25 | 6 |

| I-Phrophyllite | QDF300 | 150(Mesh) | d97, 7.30μm | 80 | 6 |

| Umgogodla | QDF300 | 300(Mesh) | d97, 4.78μm | 25 | 6 |

| I-Talcum | QDF400 | 325(Mesh) | d97,10 m | 180 | 10 |

| I-Talcum | QDF600 | 325(Mesh) | d97,10 m | 500 | 20 |

| I-Talcum | QDF800 | 325(Mesh) | d97,10 m | 1200 | 40 |

| I-Talcum | QDF800 | 325(Mesh) | d97, 4.8μm | 260 | 40 |

| I-calcium | QDF400 | 325(Mesh) | d50, 2.50μm | 116 | 10 |

| I-calcium | QDF600 | 325(Mesh) | d50, 2.50μm | 260 | 20 |

| Magnesium | QDF400 | 325(Mesh) | d50,2.04μm | 160 | 10 |

| I-Alumina | QDF400 | 150(Mesh) | d97,2.07μm | 30 | 10 |

| Amandla eparele | QDF400 | 300(Mesh) | d97, 6.10μm | 145 | 10 |

| I-Quartz | QDF400 | 200(Mesh) | d50,3.19μm | 60 | 10 |

| I-Barite | QDF400 | 325(Mesh) | d50, 1.45μm | 180 | 10 |

| I-ejenti ekhipha amagwebu | QDF400 | d50, 11.52μm | d50, 1.70μm | 61 | 10 |

| I-kaolin yomhlabathi | QDF600 | 400(Mesh) | d50,2.02μm | 135 | 20 |

| I-Lithium | QDF400 | 200(Mesh) | d50, 1.30μm | 60 | 10 |

| Kirara | QDF600 | 400(Mesh) | d50,3.34μm | 180 | 20 |

| I-PBDE | QDF400 | 325(Mesh) | d97, 3.50μm | 150 | 10 |

| I-AGR | QDF400 | 500(Mesh) | d97, 3.65μm | 250 | 10 |

| I-graphite | QDF600 | d50,3.87μm | d50, 1.19μm | 700 | 20 |

| I-graphite | QDF600 | d50,3.87μm | d50, 1.00μm | 390 | 20 |

| I-graphite | QDF600 | d50,3.87μm | d50,0.79μm | 290 | 20 |

| I-graphite | QDF600 | d50,3.87μm | d50,0.66μm | 90 | 20 |

| I-Concave-convex | QDF800 | 300(Mesh) | d97,10 m | 1000 | 40 |

| I-silicon emnyama | QDF800 | 60(Mesh) | 400(Mesh) | 1000 | 40 |