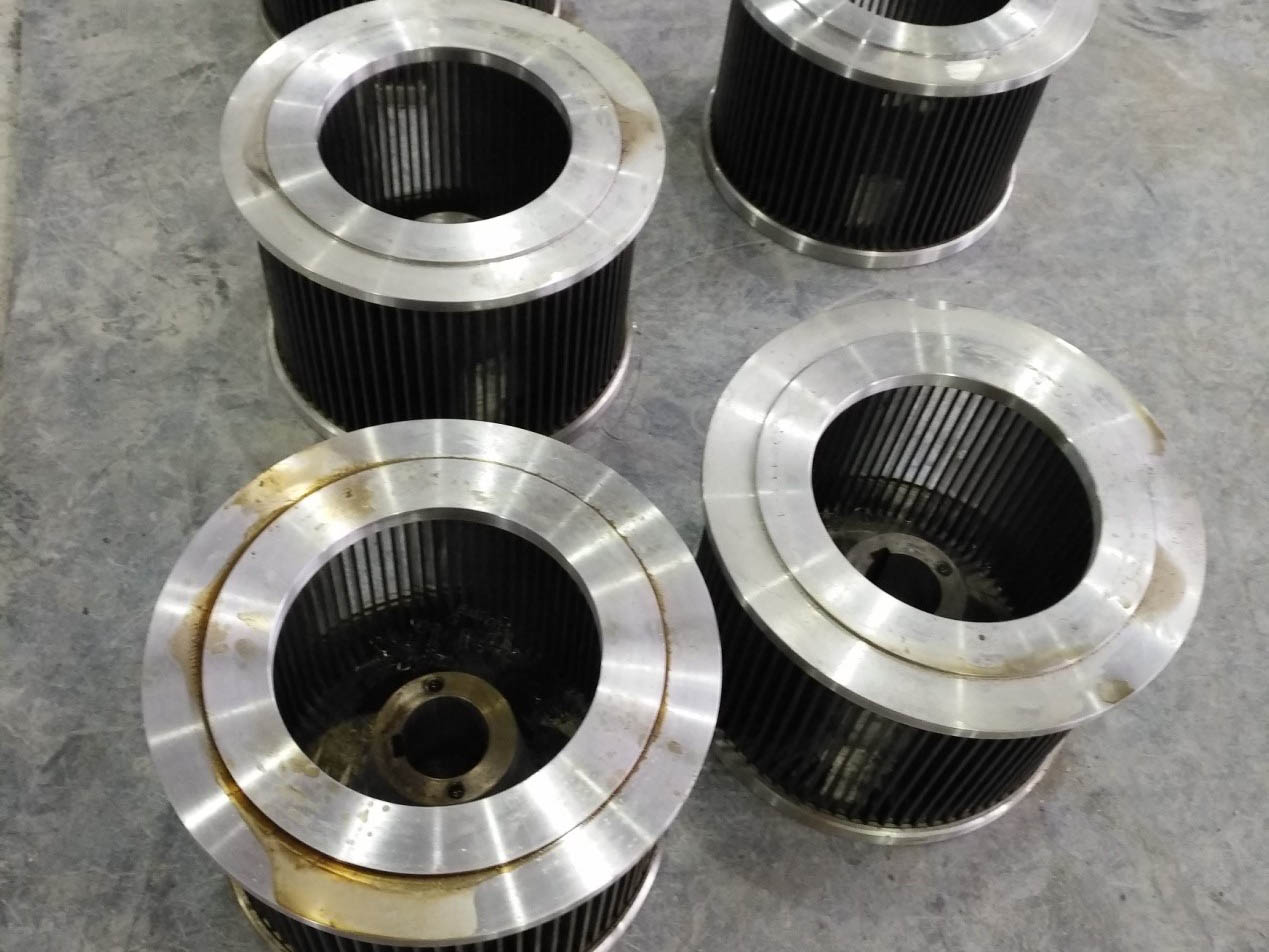

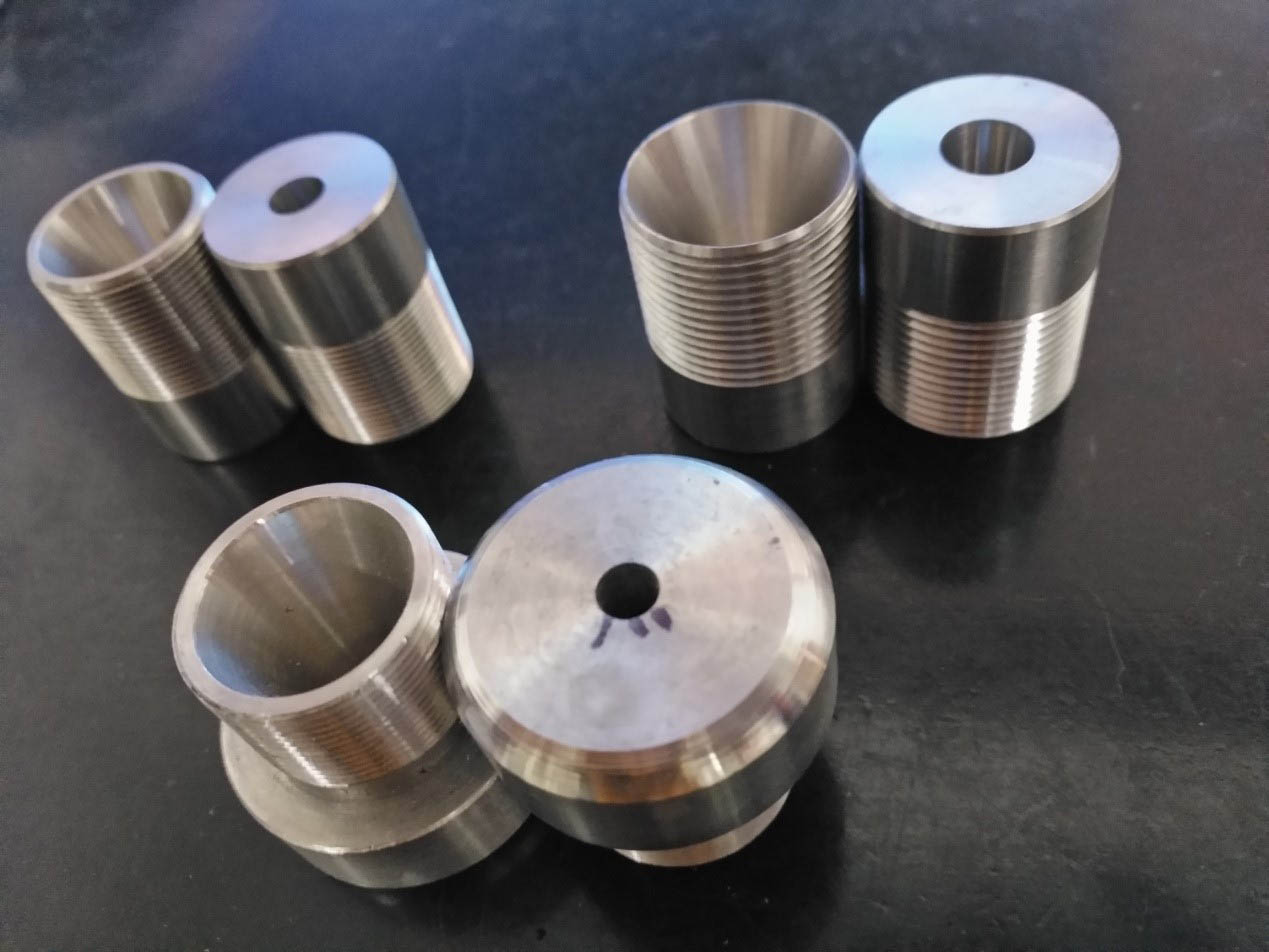

Izingxenye zeJet Mil

1.i-bearing ngaphandle, vimbela impahla ukuthi ingangeni ngaphakathi, bese u-jam.

I-2.valve kanye ne-valve core izingxenye zokuphonsa, akukho deformation ngemva kokusetshenziswa isikhathi eside.

Inqubo ye-3.CNC iqinisekisa ukunemba okuhle.

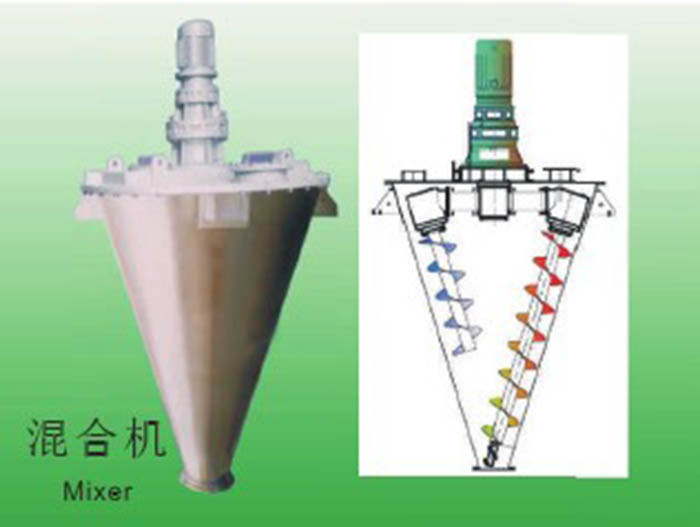

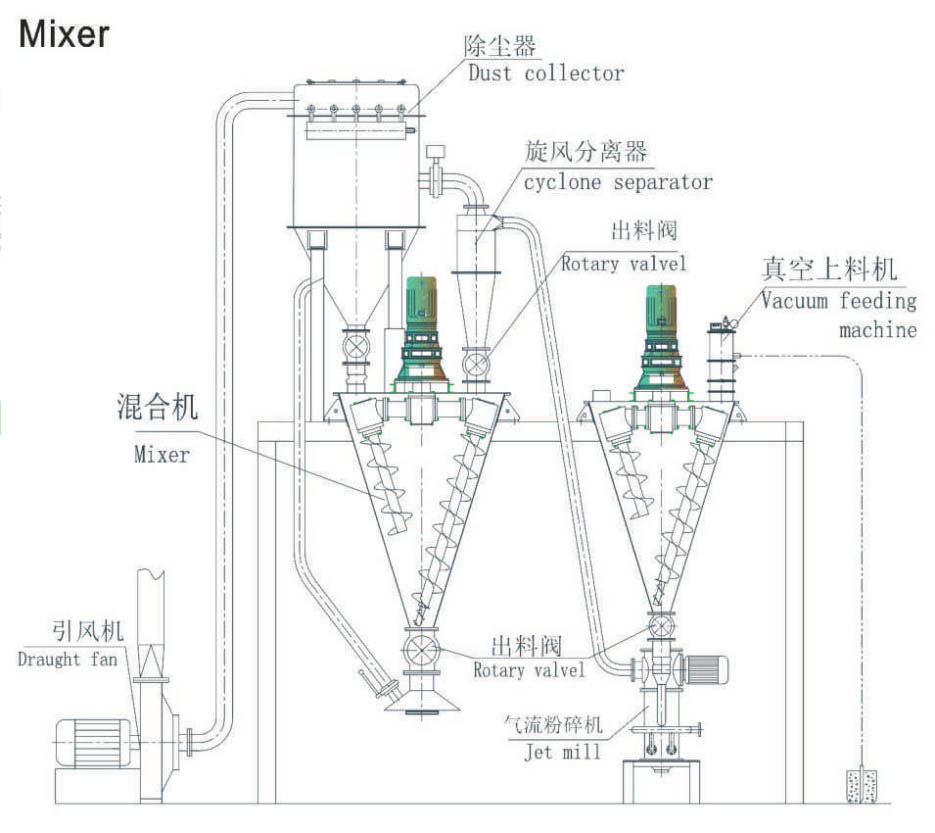

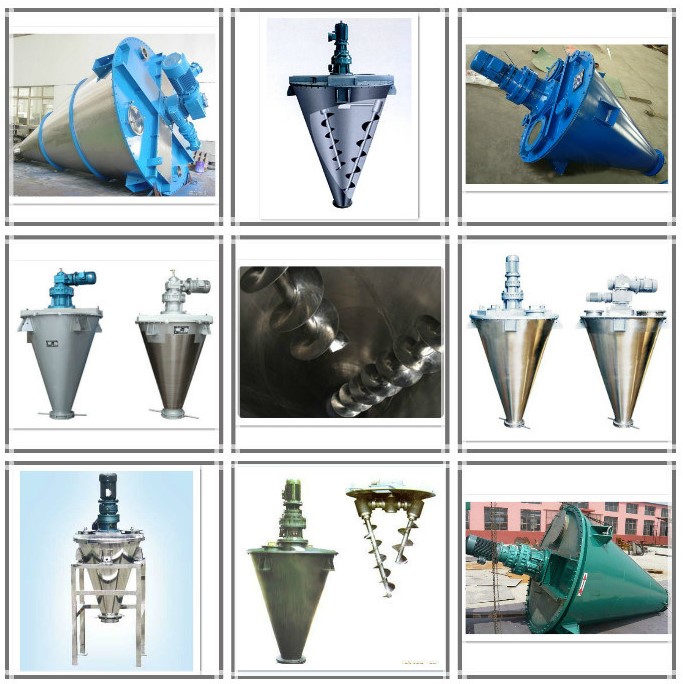

Incazelo

I-DSH double screw mixer ihlanganisa impushana, i-granule nokuxuba uketshezi. Ukuzungezisa kwe-twin screw mixer kuqedwa isethi yezinjini nezinciphisi ze-cycloid. Ngokuxutshwa kwe-asymmetric ngezikulufu ezimbili, ububanzi obushukumisayo buzonwetshwa futhi isivinini esishukumisayo sizosheshisa. Umshini wokuhlanganisa ukhuthazwa ama-spiral amabili a-asymmetric wokuzungezisa okusheshayo, okwenza amakholomu amabili asontekile angalingani agelezela phezulu esuka odongeni lwesilinda. Ingalo ephendukayo eqhutshwa i-spiral orbit, yenza i-spiral material yezinga elihlukile ibe yi-stud emvilophini, i-slocation ingxenye yento ethuthukiswayo, enye ingxenye yento ephonswa isikulufu, ukuze kuzuzwe izinto ezithwala umbuthano ogcwele zibuyekezwa njalo. Izinto ezimbili ezishiwo ngenhla zibe sezihlanganiswa futhi emgodini we-concave wesikhungo, zenze ukugeleza okuya phansi kwezinto futhi zengeze imbobo engezansi, ngaleyo ndlela yakhe ukujikeleza kwe-convective.

Isici

1.Ukuxuba okulinganayo

2.Isikhathi esifushane sokuxuba imizuzu emi-5-15

3.Hlanza ukukhishwa futhi akukho okusele

4.I-valve yokukhipha emaphakathi:

I-elekthronikhi, i-pneumatic, imanuwali (uma uthanda)

I-valve yebhola, i-flap valve, i-valve yesango lommese, i-butterfly valve (uma uthanda)

5.Main shaft seal:Stuffing seal kanye ne air purge seal

6.Drive:Siemens motor, cycloid noma gear reducer

7.Limit/ukuphepha switch (uyazikhethela)

8.Ijakhethi yokushisisa/yokupholisa uyazikhethela)

Isicelo se-cone mixer:

1.Ingxenye yempahla esebenzayo yabampofu, izinhlayiya zempushana ziyizinto ezinkulu kakhulu;

I-2.Ifanele inqubo yokuxuba i-ceramic glaze emnene, izinhlayiya zezinto ezibonakalayo azicindezelwa noma ziphukile;

3.Izinto ezizwela ukushisa ngeke zishise ngokweqile;

4.Ku-powder - inqubo yokuxuba i-powder kulula kakhulu ukwengeza izimo zokusebenza noma ukunikeza uketshezi ebuningini bezindlela zokuphuma kwesifutho;

5.I-valve engezansi ye-dislocation material elula, kusukela phansi kokuvunguza akukho okulungisiwe, ngakho-ke akukho mkhuba owenziwe ngokucindezela.

Umgomo wokusebenza:

Isihlanganisi seribhoni esivundlile esiphindwe kabili sinethangi elivundlile elimise okwe-U, ikhava ephezulu enezimbobo (noma ezingenakho), i-shaft eyodwa efakwe i-agitator yokuxuba iribhoni enezingqimba ezimbili, iyunithi yokudlulisela, ifreyimu yokusekela, isici sokuvala, isakhiwo sokukhipha nokunye. Ama-Ribbon blades ahlala ayizingqimba ezimbili. Iribhoni yoqweqwe lwangaphandle yenza izinto ezisetshenziswayo zihlangane kusukela emaphethelweni amabili kuya enkabeni futhi iribhoni yoqweqwe lwangaphakathi yenza izinto ezisetshenziswayo zisabalale ukusuka enkabeni kuye emaphethelweni amabili. Izinto zokwakha zakha i-vortex ngesikhathi sokunyakaza okuphindaphindiwe futhi ukuxuba okulinganayo kufinyelelwa.

Ukusebenza nezici:

1. Material: insimbi engagqwali 304 / 316L noma insimbi emnene Q235;

2. Ukwelashwa kwendawo: upende (insimbi emnene), i-polish/sandblasting (insimbi engagqwali);

3. I-Ribbon agitator: izingqimba eziphindwe kabili nezikhombisi-ndlela;

4. Ithangi lokuhlanganisa: ithangi elivundlile, elimise okwe-U;

5. Umphini: ovundlile, ongenalutho, umphini owodwa obalulekile;

6. Isikhathi sokuxuba: imizuzu engu-5-15;

7. Imodeli yokusebenza: ukuxuba inqwaba;

8. I-Speed reducer: i-cycloid reducer;

9. Isivinini sokuzungeza: isivinini esingaguquki;

10. Main shaft seal: (Teflon) stuffing seal noma air purge seal;

11. Ukuvula: indawo yokudla, imbobo, kanye nokuhlola / imbobo yokuxhuma;

12. I-valve yokukhipha: i-valve yokukhishwa kwe-pneumatic noma ye-manual flap;

13. Isimo sokusebenza: I-NPT (ingcindezi evamile kanye nezinga lokushisa);

14. Hhayi umsebenzi osindayo: i-mixer ayikwazi ukuqaliswa ngezinto zokulayisha;

15. Ukunikezwa kwamandla: 220V 50HZ isigaba esisodwa/ 380V 50HZ 3 isigaba;

16. Izinto zikagesi ezingenabufakazi bangaphambili (imoto, izakhi zikagesi, ikhabhinethi yokulawula);

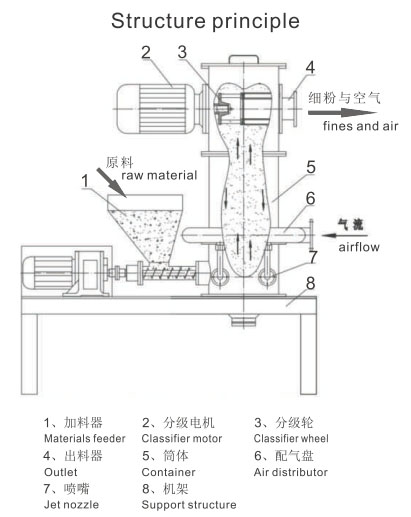

I-Jet Nozzle

Isondo Elihlukanisiwe